Automate IO-Link Sensor Data Collection for Bosch Digital Twin

CUSTOMER SPOTLIGHT

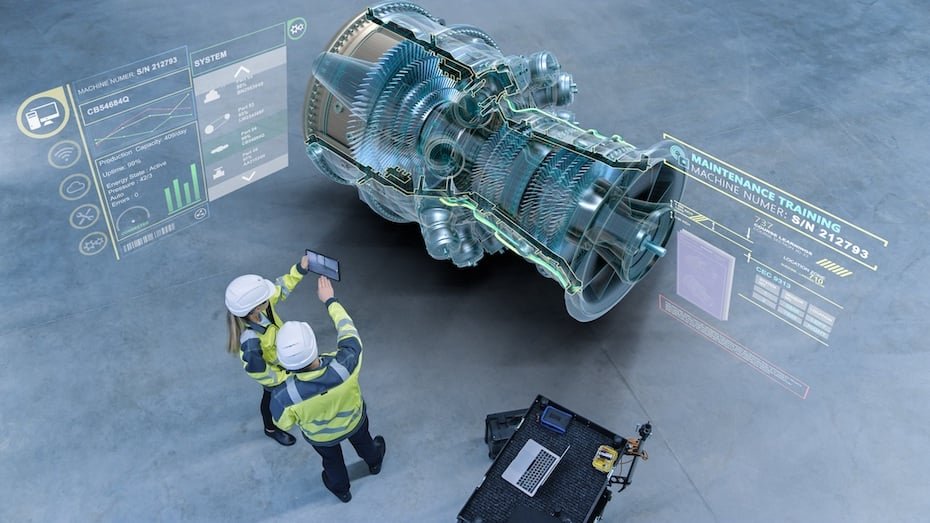

Bosch partners with Prescient to deliver this world-class Digital Twin - Integrated Asset Performance Management System (IAPM) that transforms traditional workforce into an interdisciplinary digital workforce and enables C-suite to drive business outcomes.

Rapid edge AI development for Schneider Electric

Speeds up implementation, time-to-market, and scales their edge applications with Prescient’s solution.

Automate IO-Link sensor data collection for Bosch Digital Twin

Automatically detect IO-Link Sensors and provision configurable solutions at scale.

Delivering business impact

Precision Drilling leverages the power of real-time data to optimize their critical drilling processes.

Preventing manufacturing downtime

Stanley Black & Decker scales their AI solution with Prescient’s flexible industrial data infrastructure.

Automate PLC data collection and configuration

A major oil and gas solution provider needs to collect PLC data at scale and send it to the cloud quickly.

New edge with installed base visibility

Bringing visibility into installed base in 2 weeks and improving analytical instrumentation utilization by 39%.

Scale to hundreds of edge controllers

WAGO deploys Node-RED solutions to hundreds of edge controllers and computers with Prescient.